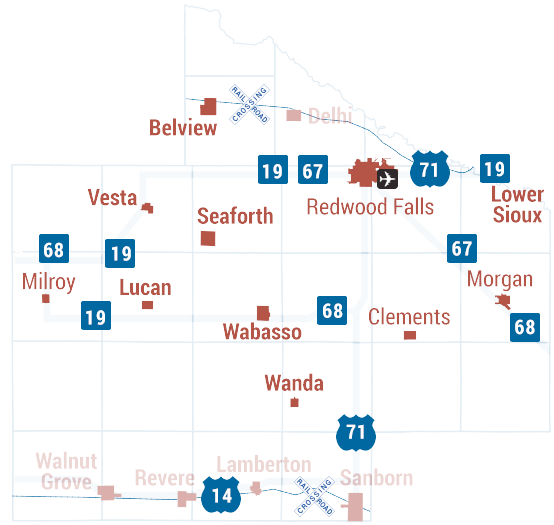

Lower Sioux Indian Community Uses Hempcrete to Build Low-Cost, Sustainable Housing

Monday, December 05, 2022

The Lower Sioux Indian Community is using hempcrete to create sustainable, low-cost housing. Earl Pendleton, Vice President of the Lower Sioux Indian Community Tribal Council, explained what hempcrete is and how it began being used.

“Hempcrete was rediscovered in the mid-1980s in France by testing the materials in a 1,500+-year-old bridge that was amazingly still in use and in great shape. The abutment holding the stones was a mixture of hemp and lime,” explained Pendleton.

“I came across the story 12 years ago while researching the environmental benefits of growing hemp, and it's ‘claimed’ 20,000+ uses for the three main parts of the plant; grain (seed), hurd (woody inner core of the stalk), and fiber (the material that wraps around the hurd),” said Pendleton.

According to Pendleton, hempcrete has been used for years in Europe and Canada and has recently become more popular in the United States. “The first hemp-lime insulated home was built in Asheville, North Carolina, in 2012 and has since been used in approximately 50 homes to date,” stated Pendleton.

Hempcrete is used as a replacement for the wall system in a conventional building – which typically consists of vinyl siding, plastic vapor barriers, OSB, batt insulation, and drywall. These conventional products can have a negative impact on carbon emissions during the production process and are detrimental to the health of inhabitants when they do not let the building "breathe" properly. “In essence, we are trapped in a plastic "bubble" that is intended to keep moisture out, but it never really does,” said Pendleton. "Hempcrete is a more sustainable option."

Pendleton said that another fantastic quality of hempcrete is that “it will also clean the indoor environment of toxins better than any air handling system currently in existence, helping inhabitants breathe clean air, all done naturally and without a duct system.”

With all these positive benefits, Pendleton wanted to find a way to bring hempcrete to the area. “We plan to build the first two hempcrete homes using the cast-in-place method where we place formwork around a timber frame and fill it with ’wet’ hempcrete. This method is the most ideal, but has limitations in that it takes five weeks to cure, slowing the build timeline.”

But this is just the beginning. "Our goal is to begin experimenting with block and prefab wall production next year once our Hemp Campus is complete. That would make hempcrete easier to build with and sell as a product outside of the community.”

Category: news

.jpg)